Apparent Porosity and Bulk Density Testing Machine - is a special apparatus that lets you see beyond your materials. It is important because it can remember how much room the article contains air and how heavy or dense. Using this device, we are able to become more familiar with materials and develop a deeper understanding that ultimately assist us in making much smarter decisions when it comes to projects. Well, fork into that machine to learn how it works.

Steps of the Test| The steps for testing depending upon how they are made on which kind of material we want to test? It means, we require a snippet of the substance you have to test. The sample is placed in a jar after we collect it. After that we have to take proper sampling of this container & put it into the testing machine. This particular device was designed to measure the material's air content and consequently density at that time. It accomplishes this by forcing the material down, then measuring how far it deforms under pressure.

The machine is helpful for getting things about material properties like you keep it on the top and put pressure to cylindrical specimen then, we are taking readings. Its like smothering your sponge to see how much it absorbs. The best way to tell if rice is fluffy or dense is through the squishing process. I understand that this is a crucial step for testing of materials, but believe me you spending some more time right now will save your troubles in the future.

There are many benefits to using this test machine The first - teaching us how various materials perform in diverse environments. For instance, if we were going to create bricks then it would be our proper preparation that ensures the strength and inelegance of these creations as elements much better than time itself. With this, we can lay different clay and obviously will perform best in your region for high grade bricks. This is important because the ideal texture of a brick can make all the difference in how well your bricks will end up.

Advantage no 2 of yay Saving by using this Machine This machine we can use it when some project is going on, and in that multiple materials are being tested out for superior quality. This is the way that we go about finding those materials that will lead to more robust, stronger bionic designs. Better materials mean They are going to be more durable, and since they will last longer (we hope), this can save us money or time in the long run when we do not have to replace them as regularly.

Each test is composed of a number of components and ideally each part should work together to validate an entire system. It starts with a bowl in which we put the material we want to test. It locks the sample between this section. It then has a piston with the material it is pushing on. This piston is essential to the test as it holds pressure that the LLC will be applied against. One is even a squishometer to show that there are some material on top of the waves. It tells us about how much the material is being compressed due to piston applied pressure. Together, they give a good measure of the volume and type (density) of an air in a material.

Describe how one machine gives us successful results, if we use some of the testing machines wrongly it yields with low values. We have to be sure that we read and follow the testing instructions, such as applying correct pressure when materials are tested. Simply speaking, if we stop and press a little too hard its results will get disturbed. Thus, it can lead to some issues in the foreseeable future including wrong choice of material for our projects.

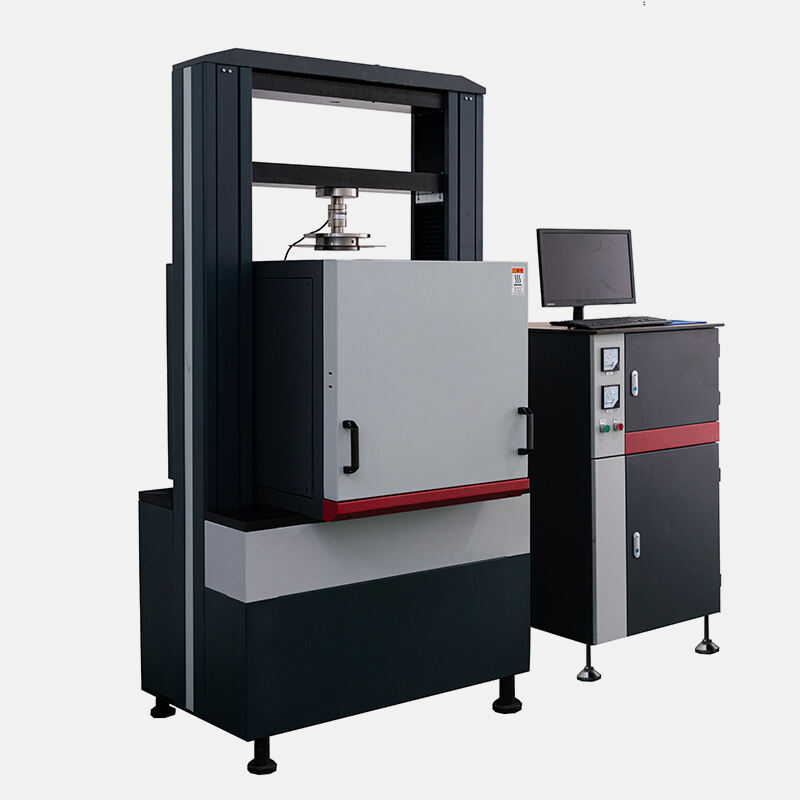

The main products of the Apparent Porosity and Bulk Density Testing Machine are high-temperature and medium-temperature heating furnaces including sample prep equipment high-temperature heating components furnace linings and computer control systems Laboratory chemical reagents for example

The company's continual RD investment, Apparent Porosity and Bulk Density Testing Machine advances and improvements in product quality have resulted in successive ISO9001, CE and SGS certifications. It also has CMC national production licenses for measuring instruments for the refractory industry, with its own intellectual property rights and more than 50 national invention patents as well as utility model patents.

Our products are widely used in the metallurgy and ceramics industries and also in building chemicals, materials, machinery and other composite material industry. Through international transportation, major institutions of the company along with national quality control agencies and scientific research centers and refractory material and other production units, as well as steel units are shipped to regions and countries in Asia, Apparent Porosity and Bulk Density Testing Machine and Middle East. Methods for transportation: We provide air transport, sea transportation, express delivery and railway transportation.

We are very proud of our top-quality equipment because we have not only experienced application engineers, but also design engineers who are attentive to the smallest details and Apparent Porosity and Bulk Density Testing Machine. With rich high-temperature testing experience we can supply custom thermal testing instruments for individual projects; provide users with high-temperature test technology, consultation and sample testing services; providing comprehensive and complete laboratory solutions.