Creep-when a material deforms over time while under load. If you think of opal as a rubber band that stretches, so far we have stretched it to 4.9 ~A which demonstrates good extensionaling behavior. When you continue to hold that same rubber band in tension for a long time then let go of it, the behavior is different-where once again, on release, the elastic shrinks back but not entirely like before. This is the same as what occurs in other materials subjected to a steady pressure. They want to know how long a material will maintain its strength under pressure before breaking or undergoing too much change. This is where creep testing helps them wider.

Creep testing is when a constant load is applied to a material and the amount of deflection (movement) can be measured over time. The machine starts adding heavier and heavier weight to determine when the material will give. This tells an engineer how long a materials absorb loads and what is the limit at which it will start to deteriorate or fail. Engineers can test materials by experimenting with various kinds to see which will keep them in the best position for a particular job.

A commonly-used tool is called a "load cell," and engineers install one on an existing creep testing machine. "...to right when this tool measures force is being applied to the material. It lets the engineers know exactly how heavy of a weight they are lifting. The machine also needs an oven, which is a furnace that the material compelled be at some temperature. The temperature is of great importance because it affects the way in which those materials respond to pressure exerted upon them.

As testing commences, the material is carefully balanced back into the machine and subjected to a liquefied weight. This weight will remain on the material for a considerable amount of time - days, sometimes weeks. The machine checks this when directed to do so during the trial using a constant weight that presses down on the material all of time. At some point, engineers write this down & circle back around to make sense of the results.

It is also vital for engineering as it provides temperature-dependent deformations in materials. We would not know how durable materials are, or even how they hold up under stress. Engineers employ this information to construct things such as secure products and structures. For instance, if they want to build a bridge then the engineers need to know for how long maybe even hundreds of years will these materials last before it starts decomposing. Without this information, the bridge may not be safe for those who use it.

Improved technology to conduct creep testing. Previously, engineers had to manually do this testing which was both time-consuming and prone to mistakes. Unfortunately, you did read it right - creep testing machines can now operate for the most part solo with minimal amount of oversight and supervision allowing such an arduous process of mechanical testing to happen in a fraction of the time while being significantly more repeatable. Engineers can simulate what materials do at different temperatures too. This allows them to anticipate how materials will behave in a range of different environments.

It is employed in many areas of engineering for creep testing. An example is - it tests the tensile strength of turbine metals. Alain Brant: Turbine is a device that converts steam energy into electrical energy. Turbines operate at high temperatures and pressures, therefore requiring that the metals used for them are very strong. This is extremely important for safe and reliable energy production; engineers need to know when these metals will failshape, so that they can be replaced in time.

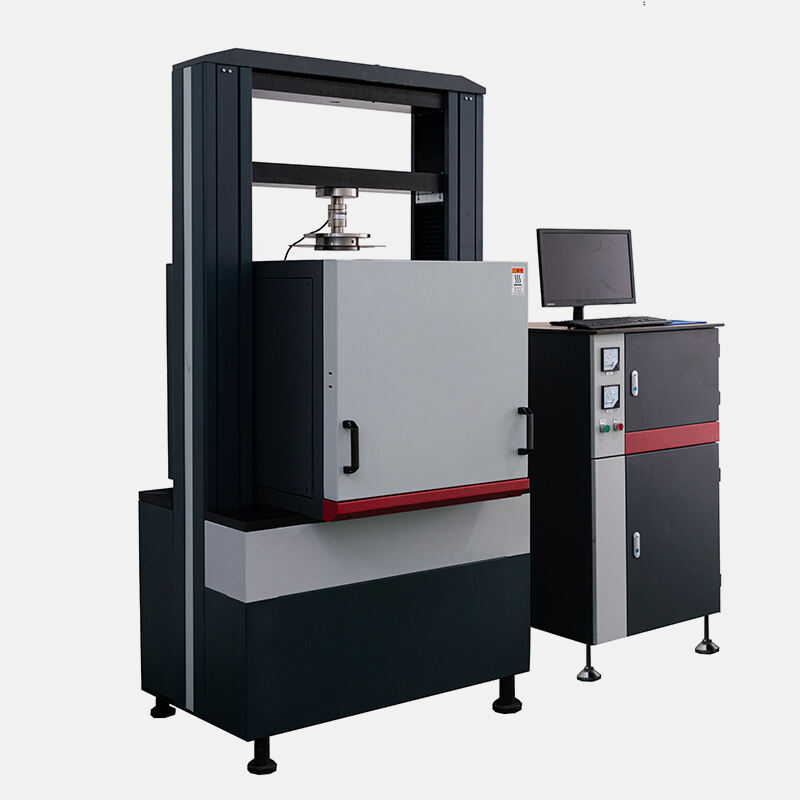

With constant RD Creep Testing machine, technological advancement and product quality improvement, the company has successively obtained ISO9001, CE, SGS and various other certifications. It also has CMC national production licenses for measuring instruments for the refractory business, as well as independent intellectual property rights and more than 50 patents for inventions in the national market and utility model patents.

Our products are used widely in the ceramics and metallurgy industries as well as in the building chemicals, materials, machinery, and other composite material industries. The company's major universities National Quality Inspection Agencies as well as scientific research centers, Refractory materials, and other production companies and steel units, through international transportation Exported to regions and countries throughout Creep Testing machine, Europe, the Middle East and Africa. Methods of transport: We offer air and sea transport, express delivery and rail transportation.

We are very proud of our top-quality equipment because we have not only experienced application engineers, but also design engineers who are attentive to the smallest details and Creep Testing machine. With rich high-temperature testing experience we can supply custom thermal testing instruments for individual projects; provide users with high-temperature test technology, consultation and sample testing services; providing comprehensive and complete laboratory solutions.

The primary products of the company are high-temperature and medium-temperature heating furnaces as well as sample preparation equipment high-temperature Creep Testing machine high-temperature furnace linings and computer-controlled systems Chemical reagents for laboratories etc