RUL (Remaining Useful Life) This gives us some idea of how long till a machine has to be repaired or replaced. For instance, a short Remaining Useful Life for another machine signifies that the system could break down in near future and we should schedule its repair. The management acronym CIC stands for "Continuous Inline Checking. This way, we can also try our devices to make sure everything is well while the machine continues working. They are quite clever as they can examine a range of machinery from teeny tiny printers to monster power stations. That is important because it helps the company keep everything working just like they need to.

Remember that one time you bought a toy, and after like 10days it was already broken? It can be very disappointing! Empirical fact: Machines break, too; however RUL and CIC testing machines take that time-bomb away. Hair dryers These unique machines might be able to determine when a machine is beginning to wear out, hence failing. Preventative Detection This is still an early example, however the operators would be able to then fix this machine before it actually breaks down. Not only does it save valuable machinery, but also prevents the life threatening accidents that might occur when a machine fails suddenly.

Frequent checks can save businesses money in the long run. If they caught an issue early, like with your tires mentioned earlier, then they won't have to spend so much in repairs. Cheaper if they find things when they are small. They also push the frequency of upgrading a machine this is known because they simply will not have to buy news machines as often. RUL and CIC testing is beneficial for the company where they get to save money, increase term of machines which could be ultimately good things.

Machines also require regular checkups, just like we visit the doctor for our health. Testing machines like RUL and CIC are used for this process which makes it simple, quick and efficient. One of the biggest successes I ever had was in automating these tests to run on their own–meaning, that no company person has to come back and check every machine by hand. — This is part two This is a time, money and energy saving trick for sure. Instead of checking each and every machine, the companies can attend to their own work.

RUL and CIC testing machines also have the ability to control a running machine. It means that the companies will not have to halt their production in order to test out these machines. This can save even more time and money for companies as it enables them to not need downtime without production while still producing crucial products. This helps organizations in having a better workflow and run more efficiently.

Testing machines for RUL and CIC would be helpful not only in ensuring that the staff is on one page, but they can also make workers communicate with each other effectively within a company. In the event of a machine that needs to be fixed, it can send a message back to maintenance team from testing machines. It speeds up machine repair cycle because maintenance team are immediately notified when the problem occurs. This means that issues can be resolved when they still new which allows the company to work better overall.

No one likes when his phone crashes in the middle of nothing. It really is... annoying and inconvenient! The same goes for machines. The testing devices like RUL and CIC test machines, help in preventing the unexpected machine problems. Regular checks of machines helps companies find issues before they turn into major problems. It is to save money, not get into accidents and make your life flow just as you would keep a phone running healthily in order for it not breaking on the floor!

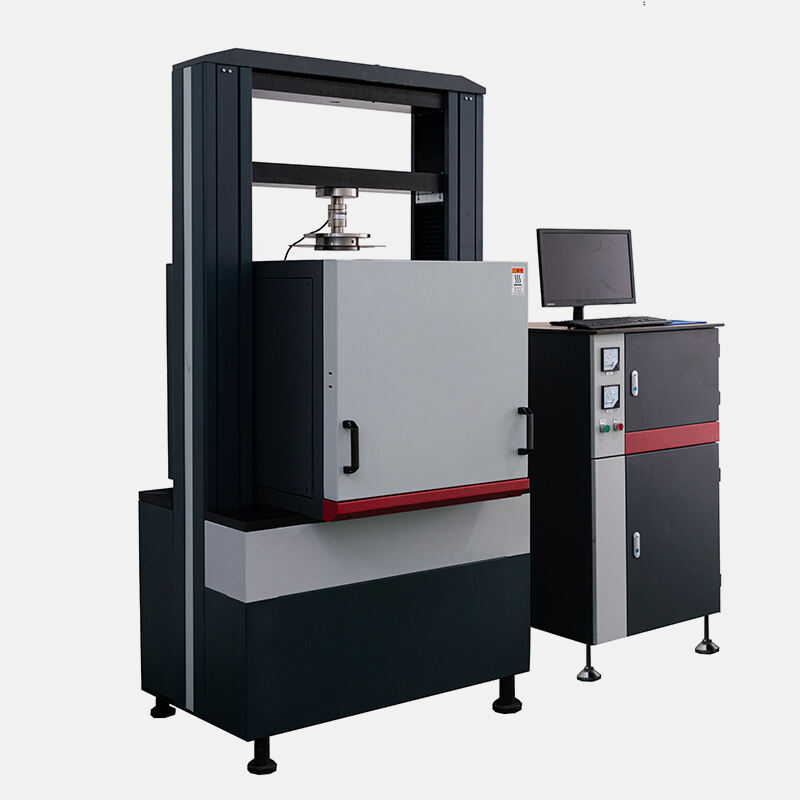

RUL and CIC Testing Machine constant RD investments, technological advancement and product quality improvements The company has repeatedly passed ISO9001, CE, SGS and other certifications. The company also holds an CMC national measurement instrument production licence with independent intellectual rights to the refractory industry, as well as more than 50 invention and utility model patents.

RUL and CIC Testing Machine superior products are due to the fact that we not only have experienced engineers in the field in addition to design engineers who pay close attention to detail and operational. We have years of expertise in high-temperature tests and we can provide custom test equipment for particular projects. We also offer high-temperature technology consultancy services as well as sample testing.

The principal products of the company are automated sample melting machines for RUL and CIC Testing Machine as well as physical test instruments for performance testing of shapes unshaped and refractory ceramic fiber products and other products including medium and high temperature heating furnaces equipment for sample preparation high temperature heating elements and the linings of high-temperature furnaces computer control systems and instruments Laboratory chemical reagents and other

Our products are used widely in the ceramics and metallurgy industries, as well as building chemicals, materials, RUL and CIC Testing Machine and other composite material industry. The main universities of the company National Quality Inspection Agencies as well as scientific research centers, refractory materials and other production enterprises and steel units, through international transportation, exported to regions and countries in Asia, Europe, the Middle East and Africa. Methods of transportation: We can support air transportation, sea transport express delivery, and rail transportation.