Wondering how you can see the same improvements with your material testing? Well, an XRF fusion machine can! Here, we tell you how fusion machines operate, how they can simplify the test processes and what wonders they could do in terms of sample preparations. You are also going to know how this machines assist us in finding new things with the use of specific melting methods. It should come as no surprise that Nanyang JZJ is one of the few companies with a strong array of fusion machines for XRF testing.

Fusion: This is essentially melting a sample using flux (a special powder) at extreme temperatures to ready it for XRF testing. This is important because it helps us to obtain precise results about the composition of the material. This is the work which fusion machines do automatically, and efficiency wise this is great than doing by hand. Back in the day, people used to manually grind and compress samples and it was a time-consuming process

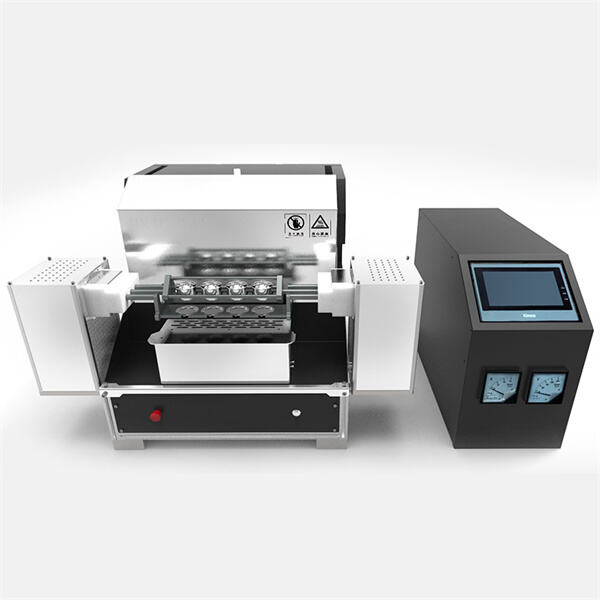

Nanyang JZJ fusion reactors have an excellent temperature control system, crucial for ensuring a complete sample melt. They can also handle loading and unloading samples; leaving nothing for you to do manually. This saves a lot of time! Considering those devices are made to produce the most perfect sample shapes there was. They are also very reliable, and as a result they give identical output each time. So you can rely on the results, which are not often case sensitive like these old methods.

Yep, a fusion machine saves so much time on sample preparation. The amchines aid in processing them quickly and ease much labour otherwise done manually. It never takes long to put everything together when it is done by hand, but the fusion machines from Nanyang JZJ can do it even more quickly all while providing a precise outcome. As a result you will be able to obtain the results faster, which is perfect for labs that test large sample numbers.

Fusion machines, the ultimate in sample preparation They can process more complex samples up to very small parts. Based on biaxial test fixtures, our device is highly versatile and accommodates a wide range of materials tested like minerals, metals and ceramics. This disadvantage of manual methods, together with the fact that not all materials are alike (with some being harder to analyze than others), makes versatility equally valuable in a testing equipment.

In addition, these machines can handle small sample sizes; if a unit is really rare or tiny because it hasa valuable thing on board etc… then will be difficult to test with the old methods. While smaller samples offer important knowledge, setting them up for this work is difficult. Fusing a sample helps reduce complexity and turn the small amount of material into an accurately analyzable form using fusion machines. This holds true even with a small sample that you will able to gain decent conclusions.

The other is, presumably, that these fusion-melting techniques can tell us what materials are comprised of and how well those materials will perform. These techniques can get down to the smallest parts per million of elements and impurities that older methods might not be able to find. Ther are many advanced techniques developed for XRF testing using Nanyang JZJ fusion machine that these machines will detect very small amount of materials with a such high level of precision. This becomes very important when we must be extremely strict (think of the precision required in scientific research or quality control).

With constant RD fusion machine for xrf, technological advancement and product quality improvement, the company has successively obtained ISO9001, CE, SGS and various other certifications. It also has CMC national production licenses for measuring instruments for the refractory business, as well as independent intellectual property rights and more than 50 patents for inventions in the national market and utility model patents.

Our products are used widely in the ceramics and metallurgy industries, as well as building chemicals, materials, fusion machine for xrf and other composite material industry. The main universities of the company National Quality Inspection Agencies as well as scientific research centers, refractory materials and other production enterprises and steel units, through international transportation, exported to regions and countries in Asia, Europe, the Middle East and Africa. Methods of transportation: We can support air transportation, sea transport express delivery, and rail transportation.

The principal products of the company are automated sample melting machines for fusion machine for xrf as well as physical test instruments for performance testing of shapes unshaped and refractory ceramic fiber products and other products including medium and high temperature heating furnaces equipment for sample preparation high temperature heating elements and the linings of high-temperature furnaces computer control systems and instruments Laboratory chemical reagents and other

We are proud of our top-quality products fusion machine for xrf to the fact that we are not just experienced application engineers, but also design engineers who pay attention to detail and operational. We have plenty of experiences in high temperature tests, and we are able to offer custom-designed test equipment for particular tasks. We also provide high-temperature technology consultancy services as well as sample testing.