Have you ever wondered how to measure iron in a piece of matter without breaking it or destroying it? This cool trick is called X-Ray Fluorescence (XRF)! One such technique is X-ray fluorescence (XRF), which uses x-rays to identify, for example in componentsиск materials. This is so critical because iron is a metal that industries require in making cars, buildings and even food.

XRF is one of the greatest wonders in that it does not harm or damage upon the object which was performed. XRF is non-destructive, so scientists suffer no adverse effects or sample damage when using X-Rays. The way it works is that a thin beam of X-rays are fired at the material. These X-rays are actually in the form of radiation and it strikes through our material which we can generalize as a block or spectrum, These x rays does strike atoms present over their way towards hitting this final layer of © ES from where while coming out details may be rastered. This excitement results in the emission of a unique type of X-ray known as a fluorescence X-ray. Those fluorescent X-rays can be detected and studied by scientists to provide information about the concentration of iron in an area. This is so important to keep the materials safe for their original use.

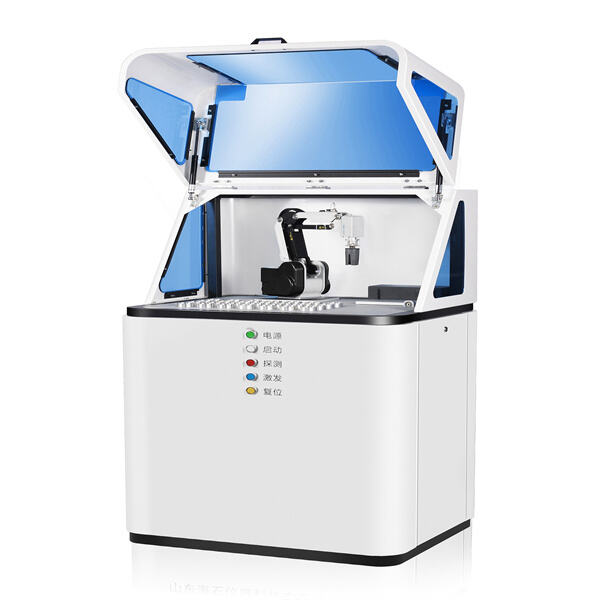

XRF is so valuable here because it can enable you to determine how much iron present in a variety of material kinds. That includes rocks, minerals and now even food! One example is the Nanyang JZJ's S-Max3000 XRF analyser. For example, this machine can measure the iron content in something like iron ore (the kind of stuff mining companies dig out of the ground). This is very helpful to these companies in order for them to know what ironcontent they have in their materials. It enables miners to understand how precious are their minerals and keep mining or not.

A further advantage of XRF is that it provides a rapid GM determination for iron masses in materials. In the olden days, when scientists were slightly less sophisticated than now (cough cough dust clouds…looking at you for shame), it could quite easily take a very long time to calculate an accurate result- hours or even days In many instances, this same kind of work can be done orders faster with XRF. This speed makes it particularly well-suited for areas where iron content needs to be determined rapidly and accurately in industrial samples.

You can easily use XRF and tell what products seem to have the most iron. Manufacturers using XRF to determine iron levels in their deodorants know for a fact that it has the exact right amount of Iron. This is very essential for so many different things, such as food and drinks or even steel that we use to build bridges and buildings. For example, XRF can be used by food companies to verify that the company's breakfast cereals and baby formulas contain enough iron in order for them to stay within FDA safe levels. In so doing, they guarantee that those calories are consumed in a healthy way (or better put, with the best nutrition possible).

With constant RD x-ray fluorescence iron concentration, technological advancement and product quality improvement, the company has successively obtained ISO9001, CE, SGS and various other certifications. It also has CMC national production licenses for measuring instruments for the refractory business, as well as independent intellectual property rights and more than 50 patents for inventions in the national market and utility model patents.

Our superior x-ray fluorescence iron concentration are due to the fact that we do not just have skilled engineers in the field as well as design engineers who pay close attention to detail and operations. With a wealth of high-temperature test experience we can supply custom tests for specific projects. We provide our customers with high-temperature test technology, consultation and test services for samples; and provide an integrated and comprehensive laboratory solution.

Our products are used widely in the ceramics and metallurgy industries, as well as building chemicals, materials, x-ray fluorescence iron concentration and other composite material industry. The main universities of the company National Quality Inspection Agencies as well as scientific research centers, refractory materials and other production enterprises and steel units, through international transportation, exported to regions and countries in Asia, Europe, the Middle East and Africa. Methods of transportation: We can support air transportation, sea transport express delivery, and rail transportation.

The most popular products of the company x-ray fluorescence iron concentration medium and high-temperature heating furnaces including sample prep equipment high-temperature heating equipment furnace linings and computer control systems laboratory chemical reagents such as