Вече си чудили как лекарите могат да погледнат вътре в тялото ви с рентген? Той може да покаже на лекаря как добре работят костите и повечето от тези други части — но без операция. XRF — анализ на рентгеновата флуоресценция, който функционира много подобно на EDXA, но се използва за широк спектър от индустрии. Разбирането, че материалите са съставени от различни елементи, е само първият стъпка, а XRF става важен. Той помага на учениците да определят кои метални или минерални елементи биха могли да присъстват. И това е изключително важно за поддържане на безопасността и качеството в различни зрели индустрии, като горнодобив, медицина и електроника. Би било трудно да се определи дали материалите са безопасни за употреба без точни резултати от XRF.

Настройка на оборудването, което измерва тези материали, за да се получат важни резултати от XRF. В електронно контролирано превозно средство това се нарича калибриране. Калибрирането е като настройката на музикален инструмент. Калибрирането е подобно на акта на настройка на гитара или друг музикален инструмент, за да произвежда правилни звуци. В случая на XRF приборите, правим калибриране, за да могат те да измерват точно. Това означава, че гарантирате, че инструмента измерва това, което трябва да измерва, и в правилното количество измерения. Калибрираните инструменти гарантират, че резултатите от XRF са точни и удостоверяват, че материалите, които тестваме, се conform към стандартите за безопасност/производителност.

Има някои добри практики, които всички трябва да следват, за да се гарантира, че данните от XRF са надеждни. Калибрирането трябва да се провежда на регулярни интервали, независимо от честотата на използването. Това е като промяната на батерейките в телевизионния пульт; само защото не го използвате всеки ден, не означава, че никога не трябва да се уверите, че все още работи. Сертифицираните референтни материали са още един инструмент, който има смисъл да се използва. Те са специални примери, които имат известни стойности и се използват за тестове дали измеренията на този конкретен инструмент са точни. Правилата за подготовкготуването и тестването на пробите трябва също да се следват внимателно! Правилното готвене на пробите и поддържането на указанията гарантира, че резултатите винаги са надеждни при нашите тестове.

Добро и внимателно приготвяне на пробите е необходимо за получаване на точни резултати с XRF. Ако пробите не са приготвени правилно, те ще дадат неточни резултати, което може да доведе до други проблеми по-късно. Потребително е също да се извърши правилна промивка, за да се гарантира, че няма замърсители, които биха могли да причинят интерференция в резултатите. Това е подобно на начина, по който миеш зеленчуци преди да ги ядеш; Не искаш бактерии, нали? Измиването и смесването на пробите тщателно също е от съществено значение. Материалът може да остане неизмерен, ако пробите не са достатъчно хомогени. Когато подготовк приготвителната подготовка е добра, това означава, че можем да измерваме с висока точност от данните на XRF.

Проблеми: Въпреки че анализът с XRF е фантастичен инструмент, понякога все още могат да възникнат проблеми. Например, някои материали може да имат области, които са трудни за откриване чрез XRF. Това може да се случи с много толщи или гъстествени материали. Точността на резултатите също може да бъде повлияна от толщината и гъстината на материалите. Все пак, решаването на тези проблеми е възможно. Можете да използвате по-продвината технология с XRF, която дори може да открива частици с размер такъв, че само един ppm. Резултатите, които дават, са по-точни благодарение на тази продвината технология. Друг подход е да анализирате пробата с множество инструменти за XRF и да сравнете резултатите. По този начин можем да видим дали резултатите се съвпадат и да имаме повече доверие в това, което откриваме.

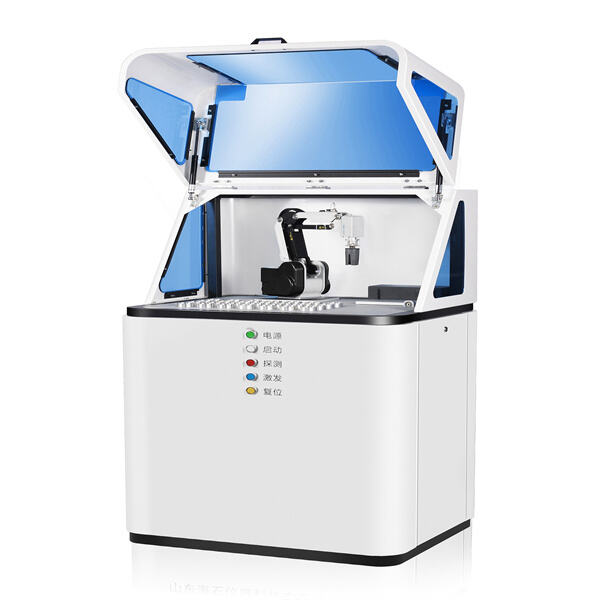

Тук, в Nanyang JZJ, знаем колко важен е точният анализ чрез XRF в различни индустрии. Поради това предлагаме най-добрия в класа инструмент за XRF, гарантирайки точни и точни резултати. Инструментите, които използваме, трябва да бъдат калибрирани по-често от обикновено и подложени на строги контроли на качеството, така че те винаги да са на високо ниво. Предоставяме също обучение и помощ, за да подкрепим клиентите си при правилната подготовка на пробите. Така те ще получат най-добрия възможен резултат, като използват нашия инструмент за XRF.

Точността на рентгеновата флуоресцентна анализа на компанията включва автоматизирано оборудване за топене на проби за спектрален анализ, както и инструменти за физически тестове на безформени, необлагодетелствани и огнестойки керамични влакна и други продукти. Средствата включват печи за средно и високо температурно отопяване, оборудване за подготовка на пробы, високотемпературни отопителни елементи, облицовките на високотемпературните печи, компютърни системи за управление, инструменти, химикали за лаборатория и други.

Продуктите ни се използват широко в метулургията, керамика, машиностроение, точност на химикали със здравословен рентгенов флуоресцентен анализ и други индустрии на композитни материали. Основните университети на фирмата и националните органи за качествена проверка, както и научноизследователските центрове, продукти за огнетвърди и други производствени бизнеси и стоманени единици са изнасяни чрез международна доставка в региони и страни по цяла Азия, Европа, Близкия изток и Африка. Методи на транспортиране: Предлагаме авио превоз, морски превоз, експресна доставка и железопътна транспортиране.

С постоянн постоянни инвестиции в НИОКР, технологическо развитие и подобряне на качеството на продуктите, компанията постоянно получава сертификати за точност на химически анализ чрез флуоресцентно иксовско излъчване, CE, SGS и други. Освен това тя разполага с национални лицензи за производство на измервателни инструменти CMC за огнестойката индустрия, както и с независими права за интелектуална собственост и повече от 50 патента за изобретения на националния пазар, както и патенти за утилитарни модели.

Гордеем се с качеството на нашите продукти за точност на химически анализ чрез флуоресцентно иксовско излъчване, тъй като не сме само експериментални инженери, но и проектиращи инженери, които обърнат внимание на детайли и операционната дейност. Имаме много опит при тестовете на висока температура и можем да предлагаме специално проектирано тестово оборудване за конкретни задачи. Предоставяме също услуги за консултации по високотемпературни технологии и пробни тестове.