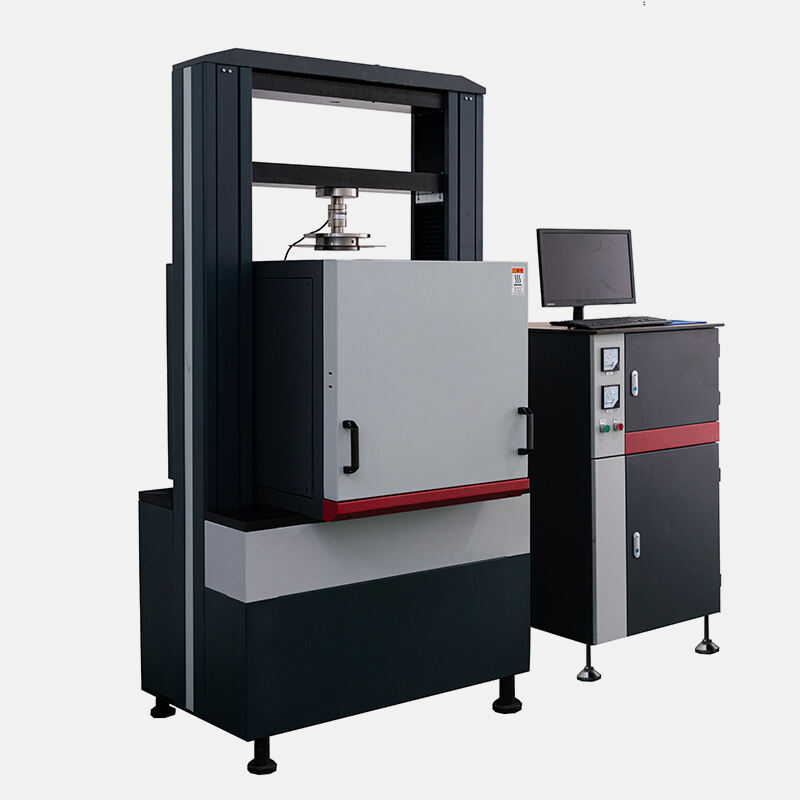

Materials testing is the testing of materials and all such physical matters. Materials that are used in building a structure, any part or appliance have to be tested before they can actually be put into use. Crucial tests are based on refractoriness under load and creep in compression testing. This becomes especially important for industries working on high heat and stress. There are a number of companies in India that create these test machines. Here are the top 5 brands:

The Best Refractoriness Under Load & Creep in Compression Testing Machine Suppliers, exporters and distributors.

The material testing in India uses special machinery to evaluate the durability and strength of different materials which play an important role. Refractoriness under load and creep in compression tests are particularly required for industries that work on high temperatures, pressure. Many makers in the Indian market already operate within this space with their own differentiated products. Check out the top 5 manufacturers of refractoriness under load and creep in compression testing machine:

First Manufacturer - First Manufacturer is a leading manufacturer of test and measurement equipment in India. Their range of refractoriness under load and creep in compression testing machines, is all following up with the international norms. It is used on machines that include features such as automated data recording and analysis, user friendly software interfaces with efficient heating parts. First Manufacturer manufactures products for ceramic, metals and glass industries as well refractories industry.

The Second Manufacturer: The best part about the testing industry that produces a lot of testing equipment for ceramic and glass segments, is known to present numerous kinds refractoriness under load or even creep in compression. Second Manufacturer has state of the art machines for delivering accurate results using advanced technology. Second Manufacturer's products have an easy-to-use software interface and also ensure the ability to quickly heat materials such as refractory bricks or cement under extreme heat, perfect for determining strength & durability.

Third Manufacturer: A key player among the Indian testing equipment manufacturers provides a comprehensive range of refractoriness under load and creep in compression machinery. These are machines built to analyze the endurance and strength of materials under harsh circumstances. With built-in features like automatic data logging, easy-to-use software interfaces and robust heating systems for ceramics to metals in all industries that require such high-temperature environments.

Fourth Manufacturer: Topping the chart of testing equipment in India, Fourth Manufacturer is proficient at producing refractoriness under load & creep in compression testing machines. In case of the ceramics, refractories and metals industries these machines according to Fourth Manufacturer are recognized for extreme accuracy as well consistent results Offering automatic data logging, built-in safety features and high throughput heating systems etc. making Fourth Manufacturer a topmost choice in this category of products.

Fifth Manufacturer: Fifth Manufacturer in India is also one of the most preferred manufacturers for testing equipment. The refractoriness under load and creep in compression testing machines in their product line is designed for the evaluation of resistance to stress, deformation capacity (creep) as well as mechanical strength under extreme conditions. These machines are equipped with automatic data recording, simple software interfaces and quality heating systems for applications in ceramics, cement and refractories.

Top 5 India's Refractoriness Under Load & Creep in Compression Testing Machine Supplier Performance Compare

My ranking is purely based on the performance comparison of these manufacturers as all I have mentioned here deliver top quality products from their portfolio with some other best in class features. High-end machines with automatic data logging and analysis separate First Manufacturer from the competition. For the ceramics and glass industries, Second Manufacturer delivers industry-focused solutions. Third Manufacturer's machines focus on safety features, while Fourth Manufacturer ensures compliance to international standards. Fifth Manufacturer has distinguished themselves by developing a user-friendly software interface in their products.

A Detailed Guide to Buying Refractoriness Under Load & Creep in Compression Testing Machine Manufacturer from India

There are many things to consider when scting a refractoriness under load and creep in compression testing machines manufacturer. Seek machines from manufacturers with a range of advanced technology features such as automatic data logging, user-friendly software interfaces and reliable heating systems. Make sure that the machines conform to international standards and can test different kind of materials including ceramics, metals or refractories. Moreover, choose a manufacturer that offers after-sales support and training services to enhance the use of equipment.

Top 5 Refractoriness Under Load & Creep in Compression Testing Machine Manufacturers India

India is home to a wide portfolio refractoriness under load and compression creep testing machine manufacturers. Top Leading Key Players of Concrete Testing Equipment Market: First Manufacturer, Second Manufacturer, Third Manufacturer Technology, International and Fourth Manufacturer. Although these brands have some similarities in offerings, all of them herald unique features that provide specific solutions to the industries. By choosing the right manufacturer, you are able to take into account things such as advanced functionality and flexibility across different material types from a single inflator-but also helpful after-sales support and training. Industries working under high temperatures and stress can achieve valid-testing results on their materials by scting the correct manufacturer.

Table of Contents

- The Best Refractoriness Under Load & Creep in Compression Testing Machine Suppliers, exporters and distributors.

- Top 5 India's Refractoriness Under Load & Creep in Compression Testing Machine Supplier Performance Compare

- A Detailed Guide to Buying Refractoriness Under Load & Creep in Compression Testing Machine Manufacturer from India

- Top 5 Refractoriness Under Load & Creep in Compression Testing Machine Manufacturers India

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK