X-रे फ्लुओरेसेंस विश्लेषण या सरलता से XRF विश्लेषण, एक अनाधारित विधि है जिसे वैज्ञानिक उपयोग करते हैं ताकि सामग्री के घटक को निर्धारित करने के लिए पता चले कि कौन से तत्व कुछ सामग्रियों का गठन करते हैं। इसके बारे में यह तथ्य कम अंधाधुंद है कि यह हमें विज्ञान के साथ विभिन्न पदार्थों के बारे में अधिक जानने की सुविधा देता है। XRF मशीन क्या है और यह कैसे हानिकारक रासायनिक विकिरण, जिसे X-रे कहा जाता है, का उपयोग करता है? यह विकिरण, जब यह एक नमूना (या सामग्री) पर पड़ता है, तो पदार्थ के परमाणुओं; या पदार्थ के छोटे भागों को उत्तेजित कर देता है। जब परमाणु उत्तेजित होते हैं, तो वे अपनी ऊर्जा को फ्लुओरेसेंट X-रे के रूप में छोड़ देते हैं। यह X-रे मशीन द्वारा पकड़ा जाता है और विश्लेषित किया जाता है ताकि नमूने में कौन से तत्व मौजूद हैं यह निर्धारित किया जा सके। इस तरह, वैज्ञानिक पदार्थों के रासायनिक गठन को समझने में सफलता प्राप्त करते हैं।

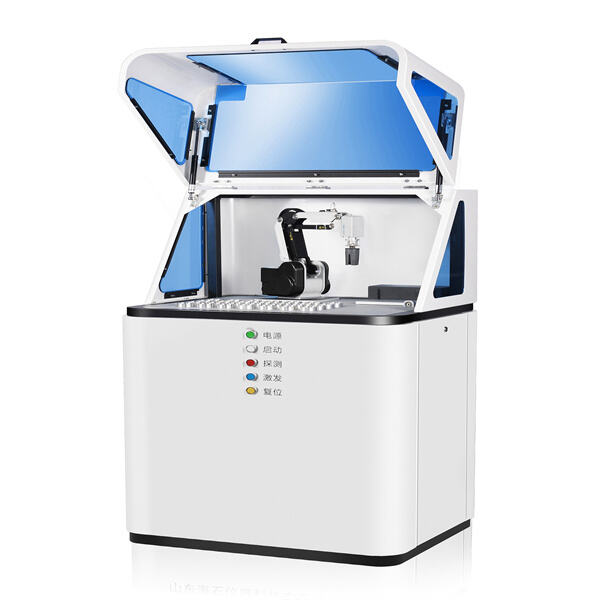

XRF विश्लेषण के लिए सबसे अधिक उपयोग किया जाने वाला और वास्तविक उदाहरण है। उदाहरण के लिए, खनिज उत्खनन खनिज को मानवीय उपयोग के लिए प्राकृतिक परिवेश से बाहर निकालने की प्रक्रिया है। फार्मास्यूटिकल उद्योग, जो दवाओं को संश्लेषित करता है, इसे उपयोग करके पदार्थों की गुणवत्ता को सत्यापित करता है। इसके अलावा, XRF का उपयोग पर्यावरण वैज्ञानिकों द्वारा मिट्टी और पानी के नमूनों पर किया जाता है ताकि प्रदूषण या पर्यावरण के लिए हानिकारक तत्वों को पहचाना जा सके। लोहा या खनिज में तत्व को कैसे बेहतर विश्लेषित किया जा सकता है? यह जानकर देखा जा सकता है कि एक जटिल सामग्री से क्या बनी है। वैज्ञानिकों को नान्यांग JZJ द्वारा विकसित उपकरणों जैसे सुधारित उपकरणों का उपयोग करके केवल कुछ मिनटों में अंतिम परिणाम को ठीक से जानने की क्षमता होगी। यह उन्हें बहुत सारे नमूनों को आसानी से विश्लेषित करने की अनुमति देता है, जो उनके कार्य के लिए महत्वपूर्ण है।

एक्सआरएफ विश्लेषण का उपयोग करने का सबसे बड़ा फायदा यह है कि यह आपके नमूने को नष्ट या बदलने वाला नहीं है। इन्हें अविनाशी परीक्षण के रूप में जाना जाता है। विश्लेषण की यह अविनाशी प्रकृति इस बात का सुझाव देती है कि परीक्षण के दौरान परीक्षण नमूने बदले या बदले नहीं जाते हैं और बाद में फिर से विश्लेषण के लिए संग्रहण में रखे जा सकते हैं। विशेष रूप से जब हम सीमित या महंगे संसाधनों के साथ सौदा कर रहे हैं, तो यह रिसाव का खतरा नहीं डालना चाहेंगे। इसके अलावा, एक्सआरएफ विश्लेषण तेजी से होता है और अत्यधिक सटीक है। ऐसे नमूनों को निम्नतम पूर्व-इलाज की आवश्यकता होती है ताकि वैज्ञानिकों को तेजी से परिणाम निकालने में मदद मिल सके। बजाय इसके, यह शोधकर्ताओं को अपने जीवन के दूसरे आधे हिस्से में खोज पर केंद्रित होने की अनुमति देगा - परिणामों का अध्ययन और व्याख्या करना।

ऐसा कहने से, XRF विश्लेषण अपनी सीमाओं से रहित नहीं है। एक प्रमुख सीमा X-रे की नमूने में प्रवेश गहराई है। हमें अंदर के परमाणुओं को देखने की क्षमता होनी चाहिए, जिसके लिए X-रे के लिए पारदर्शी होना आवश्यक है। मोटे या अधिक घनी नमूनों के लिए, यह उनमें अधिक गहरे से डेटा निकालने को सीमित करता है। इसके अलावा, XRF विश्लेषण केवल भारी तत्वों (कार्बन/हाइड्रोजन/नाइट्रोजन) के लिए वास्तव में उपयुक्त है। ये अधिकांश पदार्थों में सर्वव्यापी हैं, लेकिन XRF मशीन के लिए समस्याजनक हैं। XRF विश्लेषण का अंतिम, लेकिन कम से कम हिस्सा तकनीकी ज्ञान की मांग करता है। मशीन को सही ढंग से संचालित करने और उसके परिणामों को समझने के लिए विशिष्ट प्रशिक्षण की आवश्यकता होती है।

पिछले कुछ वर्षों में X-रे फ्लुओरेसन्स में कई उत्साहजनक विकास और नवाचार हुए हैं। समय के साथ XRF मशीनों को अधिक सटीक, विश्वसनीय और तेज बनाया गया है, जिससे वे पिछले समय की तुलना में बेहतर है। उदाहरण के लिए, आधुनिक प्रौद्योगिकी और उच्च-प्रदर्शन डिटेक्टर वाले नैन्यांग JZJ स्वचालित XRF विश्लेषण करने वाले यंत्र, जो प्रत्येक नमूने में बहुत कम सांद्रता में तत्वों को ढूँढ़ने के लिए है। वैज्ञानिकों को इस स्तर की विस्तृत जानकारी प्राप्त करने की सुविधा मिलती है, जिससे सबसे जटिल सामग्रियां (जो आमतौर पर परीक्षण को प्रतिरोध करती हैं) पर भी परिणाम प्राप्त होते हैं। इसके अलावा, ये विकास नमूनों की विविधता के अनुसंधान में महत्वपूर्ण भूमिका निभाते हैं, जिससे शोधकर्ताओं को पहले दुर्लभ माने जाने वाले नमूनों की संरचना के बारे में जानकारी प्राप्त होती है।

हमारे उत्पाद x-रे फ्लुओरेसेंस विश्लेषण, रासायनिक विश्लेषण के लिए इस्तेमाल किए जाते हैं, जो धातुविद्या और केरामिक उद्योगों में इस्तेमाल किए जाते हैं, साथ ही इमारतों के मशीनों, रासायनिक पदार्थों, निर्माण सामग्री और विभिन्न अन्य संयुक्त सामग्री के उद्योगों में भी। अंतरराष्ट्रीय परिवहन के माध्यम से, कंपनी के मुख्य संस्थान राष्ट्रीय गुणवत्ता नियंत्रण एजेंसियों और वैज्ञानिक अनुसंधान केंद्रों के साथ, तापमान पदार्थ और अन्य उत्पादन इकाइयों और इस्पात इकाइयों को एशिया, यूरोप और मध्य पूर्व के देशों और क्षेत्रों में निर्यात किया जाता है। परिवहन विधियाँ: हम समुद्री परिवहन, हवाई परिवहन, त्वरित परिवहन और रेल परिवहन प्रदान करते हैं।

कंपनी का निरंतर RD निवेश, x-रे फ्लुओरेसेंस विश्लेषण रासायनिक विश्लेषण में प्रगति और उत्पाद गुणवत्ता में सुधार ISO9001, CE और SGS प्रमाण पत्रों के परिणाम है। इसके पास मापन यंत्रों के लिए CMC राष्ट्रीय उत्पादन लाइसेंस भी है, जिसमें अपने आपके बौद्धिक सम्पत्ति अधिकार और 50 से अधिक राष्ट्रीय आविष्कार पेटेंट और उपयोगी मॉडल पेटेंट भी शामिल हैं।

हमारे शीर्ष गुणवत्ता के उत्पाद हैं क्योंकि हमारे पास क्षेत्र में अनुभवी इंजीनियर हैं, x-रे फ्लुओरेसेंस विश्लेषण रासायनिक विश्लेषण के अलावा जो विवरणों और संचालन पर ध्यान देते हैं। अनुभवी उच्च तापमान परीक्षण के अनुभव से हम व्यक्तिगत परियोजनाओं के लिए सटीक परीक्षण यंत्र प्रदान कर सकते हैं। हम उपयोगकर्ताओं को उच्च तापमान परीक्षण प्रौद्योगिकी की राय भी दे सकते हैं और नमूनों का परीक्षण कर सकते हैं; और पूर्ण और अधिकृत प्रयोगशाला समाधान भी प्रदान कर सकते हैं।

कंपनी द्वारा प्रदान किए जाने वाले मुख्य उत्पादों में स्पेक्ट्रल विश्लेषण के लिए और भौतिक प्रदर्शन परीक्षण यंत्रों के लिए स्वचालित नमूना पिघलाने वाले मशीन शामिल हैं, जो एक्स-रे फ्लुओरोसेंस विश्लेषण, रासायनिक विश्लेषण, आकारहीन केरामिक फाइबर, प्रतिरोधी उत्पाद और अन्य उत्पादों के लिए उपयोग किए जाते हैं, मध्य और उच्च तापमान गर्म करने वाले कamine, नमूनों की तैयारी के लिए उपकरण, उच्च तापमान गर्म करने वाले तत्व, उच्च तापमान फर्नेस लाइनिंग, कंप्यूटर कंट्रोलिंग सिस्टम, यंत्र, प्रयोगशाला रासायनिक क्षारज और अन्य।