X-ray fluorescence, or sometimes called "XRF," is a unique and exciting khoa to probe what a variety of materials are made of. In this system, X-rays — a sort of energy that is capable of traveling through objects — cause the atoms contained in a substance to emit X-rays of their own. When these atoms emit X-rays, that informs us about exactly what elements exist in that material. This marvelous tech has sincerely evolved the way of research in industry and science. Such advanced XRF machines are like those offered by Nanyang JZJ, who help with advanced technology to help a business learn more about their materials.

So how is X-ray fluorescence actually done? It begins when an X-ray beam is focused on a substance. When the X-ray strikes the material, it causes the atoms within it to emit fluorescent X-rays. The fluorescent X-rays are specific to each kind of element present in the material. An XRF detector detects these emitted X-rays and allows scientists to determine the composition of the material, such as its purity and whether there are other undesirable substances present. It would be like an awesome game of hide-and-seek with science! Like discovering lost valuables, scientists are able to delve into the contents of a material.

Now, let’s get into the science of X-ray fluorescence. This technology is all about the interaction of atoms and energy with each other. Atoms have varying energy levels–high or low. When an atom absorbs energy, such as when it’s hit with X-rays, its electrons become excited, jumping to a higher energy level. As these electrons return to their regular state, they emit X-rays. These unique X-ray signatures serve as fingerprints for the material, allowing scientists to find out what the material is made of. As this technique is highly exact, but modern great technique is often used in leading fields like aerospace, mining, medicine, and environmental science, which serves as a useful tool for researchers.

X-ray fluorescence, one of the most useful methods of examination, can see deeply into the materials at the very, very small atomic level. In other words, even for very rare traces of specific components in a sample, scientists are able to detect and characterize them. XRF is also sensitive enough to measure minor variations in the formulation of metals, glass, and ceramics—quite valuable to scientists working with these products. This technology can also be used to detect metal parts in waste and contamination. For example, Environmental Regulation Environmental regulation is a significant area of Environmental Law because it helps keep our environment clean and safe by regulating hazardous waste and minimizing pollution.

The technique of X-ray fluorescence was developed in the early 1900s, and has continuted to evolve and improve ever since. Not completely universal and must be fully employed by scientists and researchers to get the best out of it. They need to consider the material they're analysing and how the XRF machine operates. It is also important to have expert people who can handle this technology and interpret the data it generates. Doing this will make sure that the information is utilized appropriately and that XRF technology continues to develop. Nanyang JZJ’s instruments continue to lead the forefront of scientific research, providing solutions to problems for decades to come.

Through continuous RD investments, technological advancement and product quality improvement, the company has successively obtained ISO9001, CE, SGS and various other certifications. It also has CMC national measuring instrument production license for the working principle of x-ray fluorescence, which is backed by independent intellectual property rights, and more than 50 patents for inventions in the national market as well as utility model patents.

Our working principle of x-ray fluorescence products are due to the fact that we do not just have skilled application engineers and design engineers, but also designers who are attentive to the smallest details and operational. With rich high-temperature testing experience we can supply custom tests for specific projects. We provide our customers with high-temperature test technology, consultation and testing of samples; as well as an integrated and comprehensive laboratory solution.

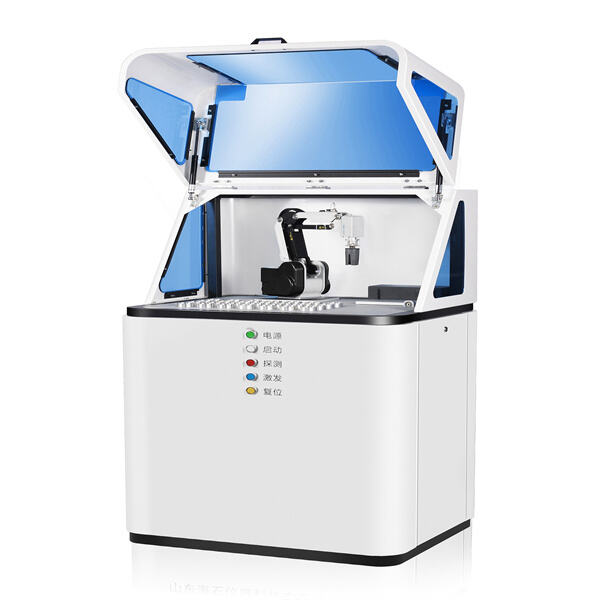

The working principle of x-ray fluorescence of the company are automatic sample melting equipment for spectral analysis as well as physical performance testing instruments for shapeless unshaped and refractory ceramic fiber products and other products medium and high temperature heating furnaces sample preparation equipment high temperature heating elements the linings of high-temperature furnaces computer control systems instruments Laboratory chemical reagents and other

Our products are used widely in the ceramics and metallurgy industries, as well as building chemicals, materials, working principle of x-ray fluorescence and other composite material industry. The main universities of the company National Quality Inspection Agencies as well as scientific research centers, refractory materials and other production enterprises and steel units, through international transportation, exported to regions and countries in Asia, Europe, the Middle East and Africa. Methods of transportation: We can support air transportation, sea transport express delivery, and rail transportation.