Factors affecting the load softening temperature of refractory materials

The load softening temperature is the temperature at which the refractory material reaches a certain compression deformation under the combined action of a certain heavy load and heat load. It is a high-temperature mechanical property of the refractory material measured by the constant load continuous heating method, which characterizes the ability of the refractory material to resist the combined action of heavy load and high temperature heat load and remain stable.

The load softening temperature and deformation temperature curves of various refractory materials, that is softening process are not the same

Factors affecting the load softening temperature: The initial load softening temperature and load softening deformation temperature curve of various refractory materials are different, which mainly depends on the chemical mineral composition of the product and is also related to its macroscopic structure to a certain extent. Among them, the most obvious factors are the following: the type and nature of the main crystal phase and the bonding state between the main crystal phase or between the main crystal phase and the secondary crystal phase: the nature of the matrix and the quantitative ratio and distribution state of the matrix to the main crystal phase or the main crystal phase and the secondary crystal phase. In addition, the compactness and porosity of the product also have a certain influence. When the refractory product is completely composed of single-phase polycrystalline, the load softening temperature of the product corresponds to the melting point of the crystal phase. For example, the load softening temperature of high-purity refractory products composed of high-melting point crystals is very high. The load softening temperature of high-purity sintered corundum bricks can be as high as 1870℃.

When the high melting point crystals in the product contact or intertwine with each other to form a strong network, the load softening temperature must be higher. On the contrary, it is understood that when the Ri'an crystal phase is isolated, its load softening temperature must be lower. For example, the phase composition of silica brick is mainly tridymite and a small amount of cristobalite. Tridymite forms an intertwined network structure of lance-shaped twin crystals in the brick, so the softening temperature under load is generally very high. The starting softening temperature is mostly above 1650°C, and some are as high as 1680°C, which is higher than the melting point of tridymite (1670°C). ℃). Another example is ordinary magnesia bricks. The melting point of the main crystal phase periclase is as high as 2800°C. However, because the main crystal phase is isolated, the load softening starting temperature is only 1550°C.

When there is a matrix in the product in addition to the high melting point crystal phase, whether the matrix is easy to decrease with the temperature at high temperature and the number and distribution of the matrix have a significant impact on the load softening temperature. For example, the main crystal phase of clay bricks and high-alumina bricks with low AL2O3 content is mullite, because they contain more SiO2-rich glassy matrix, and mullite crystals are isolated and dispersed in it, and the matrix is at 1000°C. Softening begins below, so the temperature at which softening and deformation begins is lower and decreases as the matrix content increases, that is, as the ratio of mullite to matrix content decreases. In addition, since the viscosity of this kind of matrix increases slowly with temperature, the deformation temperature range is wider. Another example is that the main crystal phase periclase of ordinary magnesia bricks is mostly surrounded by a matrix, and this matrix is composed of fusible silicate crystals. The load softening temperature of the product is controlled by the matrix, so it is low. Moreover, after the matrix is melted, its viscosity is very low, so the sample is prone to sudden rupture. Another example is that silica bricks have a very high load softening temperature. In addition to the skeleton composed of tridymite, it is also related to the matrix of high viscosity glass phase. The product has high porosity, which can reduce the starting point of load softening.

Recommended Products

Hot News

-

Function and use of refractoriness test furnace

2025-07-01

-

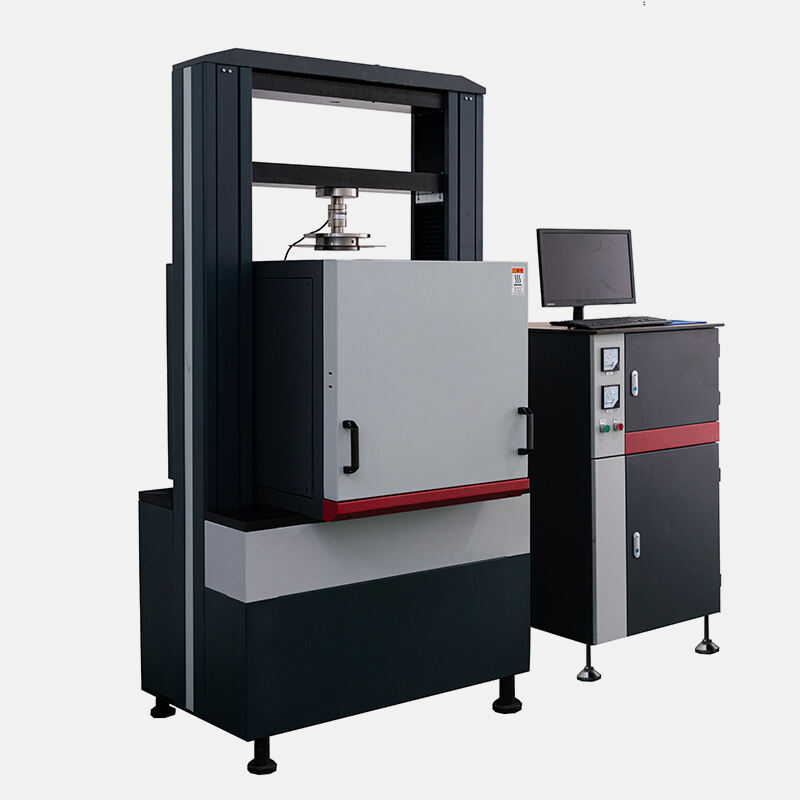

High temperature load soft creep tester test material type

2025-06-23

-

Installation method and precautions of high temperature bending test machine

2025-06-18

-

Refractoriness under load (RUL) and creep in compression (CIC) testing machine purchasing process and precautions

2025-06-12

-

JZJ Testing Equipment HT706 High Temperature Load Softening Creep Tester was successfully exported to Uzbekistan, helping the Central Asian refractory industry upgrade--Title

2025-05-29

-

Application and characteristics of the Apparent porosity volume density testing machine

2025-05-19

-

The main application of lithium tetraborate

2025-05-13

-

Is it possible to use XRF melting sample for pure copper?

2025-05-08

-

Box-type resistance furnace in jewelry welding

2025-04-27

-

Advantages and Disadvantages of High Temperature Muffle Furnaces for Heat Treatment

2025-04-21

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK