Guía de mantenimiento y solución de problemas de la máquina de fusión

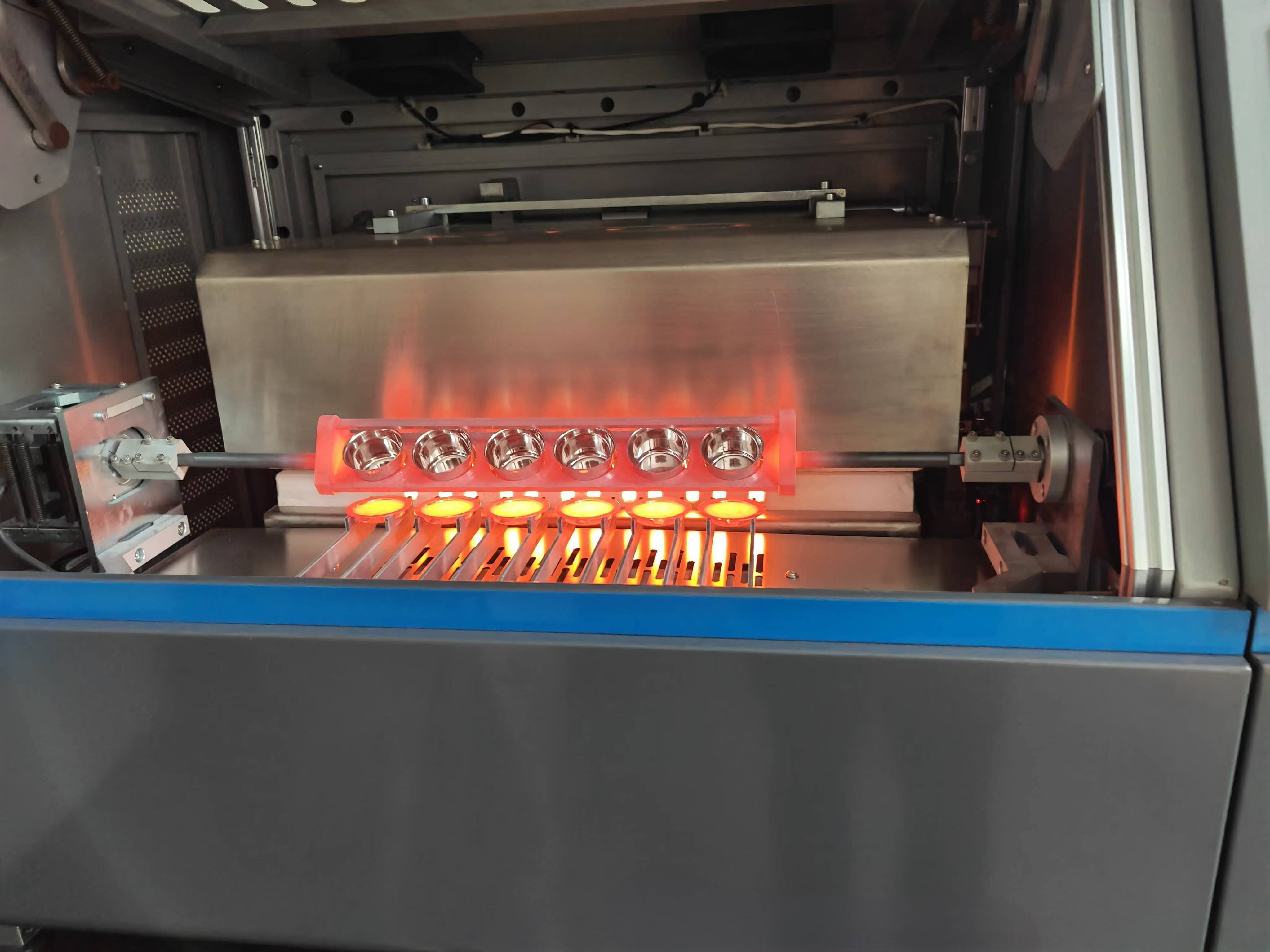

Una máquina de fusión es un dispositivo utilizado para procesar plásticos. Calienta los plásticos sólidos y los derrite, y luego forma la forma deseada a través de un molde. Sin embargo, si no se realizan mantenimientos y cuidados regulares, el equipo puede fallar, lo que resulta en una reducción de la eficiencia de producción o incluso detener la producción. Por lo tanto, a continuación se presenta una guía de mantenimiento y solución de problemas para la máquina de fusión para ayudarte a mantenerla y usarla mejor.

1. Mantenimiento y limpieza: La máquina de fusión acumulará mucha basura y suciedad durante su uso, y estas acumulaciones afectarán el rendimiento y la vida útil del equipo. Por lo tanto, es muy importante limpiar y mantener el equipo regularmente. Se recomienda limpiar el equipo cada semana y usar un limpiador especial para eliminar residuos e impurezas.

2. Verifique el calentador: El calentador del equipo es uno de los componentes principales y su funcionamiento normal es esencial para la operación estable del equipo. Por lo tanto, es necesario verificar el estado de funcionamiento del calentador regularmente para asegurarse de que calienta correctamente. Si es necesario, se puede reemplazar el calentador dañado para mantener el funcionamiento normal del equipo.

3. Mantenga el molde: El molde es un componente clave de la máquina de fusión para procesar plásticos, y su calidad y estado afectan directamente la calidad del producto. Por lo tanto, es necesario revisar regularmente el desgaste y daños del molde y reemplazarlo a tiempo. Además, se debe prestar atención a la limpieza y mantenimiento del molde para asegurar su efecto de uso a largo plazo.

4. Verifique el sistema hidráulico: El equipo generalmente está equipado con un sistema hidráulico para controlar la apertura y cierre del molde. Si el sistema hidráulico falla, el equipo puede no funcionar correctamente. Por lo tanto, es necesario revisar regularmente el estado de funcionamiento del sistema hidráulico, verificar si el aceite en el tanque es suficiente, si hay fugas u otros problemas, y reemplazar el aceite hidráulico o reparar el sistema hidráulico según sea necesario. 5. Solución de problemas: Si el equipo falla, es necesario verificarlo y solucionar los problemas a tiempo. Por ejemplo, si la temperatura del equipo es inestable, puede ser causada por un calentador dañado o un controlador de temperatura defectuoso, lo cual necesita ser reemplazado o ajustado según corresponda. Otros fallos también pueden ocurrir, como el atasco del molde, fallo del sistema hidráulico, etc., lo cual requiere diagnosticar y reparar problemas específicos. En resumen, el mantenimiento y la solución de problemas de la máquina de fusión son clave para garantizar el funcionamiento normal y la eficiencia productiva del equipo. Al limpiar, inspeccionar y mantener regularmente, se puede extender la vida útil del equipo y evitar pérdidas causadas por fallos. Si el equipo falla, debe eliminarse el problema a tiempo para reanudar la producción normal lo antes posible.

Productos Recomendados

Noticias de actualidad

-

Ventajas y Desventajas de los Hornos Eléctricos de Alta Temperatura para Tratamiento Térmico

2025-04-21

-

¿Cómo elegir un horno de mufla adecuado para el temple a alta temperatura?

2025-04-15

-

¿Cuáles son las medidas de mantenimiento para el probador de permeabilidad al aire?

2025-04-02

-

¿Cuál es la diferencia entre la máquina de fusión de aleaciones con pre-oxidación de un botón y la máquina de fusión común?

2025-03-25

-

El arte crea calidad ¡La empresa de pruebas Nanyang JZJ entregó con éxito 10 hornos eléctricos de alta temperatura personalizados para ayudar al desarrollo de alta calidad de la industria refractaria!

2025-03-17

-

Cómo abrir la puerta de un horno de matraz a alta temperatura mientras está caliente

2025-03-11

-

¿Cómo controlar la temperatura y el tiempo de calentamiento de la máquina multifunción de fusión?

2025-03-05

-

La mayor ventaja del método de fusión de la máquina de fusión automática

2025-02-25

-

Juntos construimos un futuro de calidad - Los clientes sudafricanos compraron 3 conjuntos de máquinas de fusión T6 en lotes y los entregaron con éxito, y servicios eficientes ayudan a la mejora minera global.

2025-02-22

-

Análisis detallado de las ventajas de usar una máquina multifuncional de fusión por inducción de alta frecuencia

2025-02-18

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK