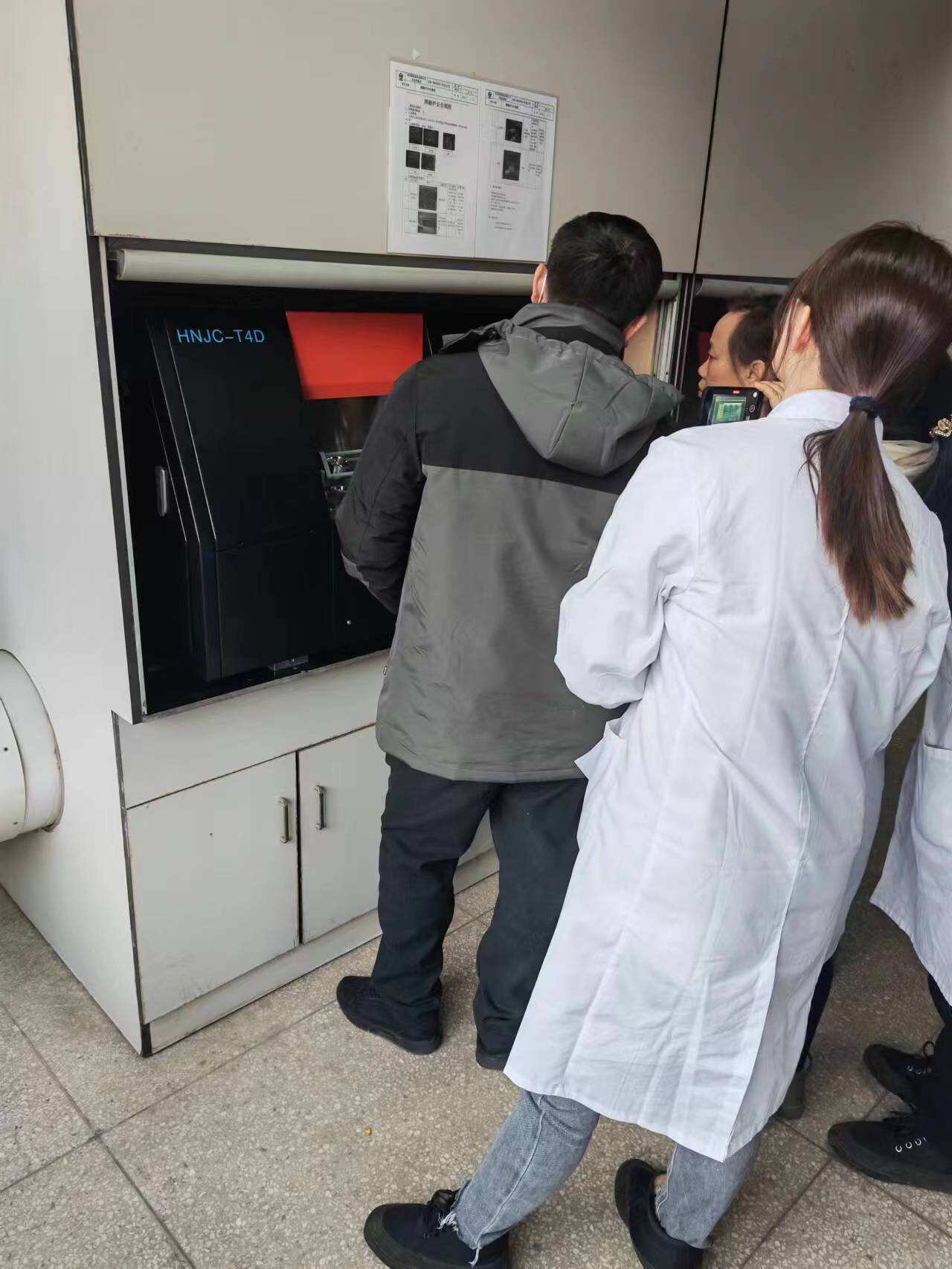

Basic operation of XRF fusion machine

The XRF fused bead sample preparation machine is a sample preparation instrument that uses glass melting method to prepare glass melts and uses AAS, ICP, and X-fluorescence analysis. It basically eliminates the mineral effect and the enhanced absorption effect of the matrix, and has high precision and good accuracy in measurement;

The heating methods used for high-temperature melting are: gas heating, resistance radiation heating, and high-frequency induction heating.

The melting machine is mainly divided into three types: high-frequency induction melting machine, electric heating melting machine, and gas melting machine.

Typical sample types of melting machines include oxides, sulfides, silicates such as mining ores, metallurgical ores, concentrates, etc. It can be widely used in steel, metallurgy, chemical industry, geology, cement, ceramics and other industries.

Basic operation of the melting machine:

1. Turn on the power of the water cooler, start the water cooling system, and after confirming that the cooling water is unobstructed and there is no water leakage, turn on the power of the melting machine.

2. Open the cover of the melting machine operation table, place the large crucible with the weighed sample and the small crucible for demolding on the ceramic bracket in the working coil, and stick them in the groove. Do not let them touch the working coil.

3. Click Manual on the main screen to enter the manual operation sample preparation mode. Press the start button on the front panel, the heating lamp on the panel flashes, and there is a beeping sound, indicating that the equipment is working normally.

Click the slider to adjust the temperature value to 1050 degrees. After the sample is completely melted into liquid, click the swing switch to swing the crucible, adjust the swing speed to 1000~1400, and drive away bubbles.

Continue heating for 5~10 minutes, stop swinging when the heating coil rotates to a horizontal position, pour the sample into the small crucible with crucible tongs and spread it horizontally. Press the stop button on the panel to stop heating.

4. Use natural cooling or click the air cooling button for forced cooling. The time is controlled by itself until the process is completed or forced to stop. After cooling, take out the sample and the sample preparation is completed.

5. Exit the program, turn off the power of the fusion machine, and close the cover. Turn off the power of the water cooler.

The XRF fusion machine uses a touch screen display control, with a friendly interface, easy operation, and a high degree of automation. It has the characteristics of fast heating, temperature control, energy saving, and stable operation. The temperature can be as high as 1100℃. It has excellent melting effect on refractory materials, good reproducibility of fusion sample preparation, excellent performance of various indicators, and good cost performance.

How to improve detection efficiency:Automatic Fusion Machine for XRF

ALLThe advantages of fire assay in gold ore sample experiments are mainly reflected in the following aspects:

NextRecommended Products

Hot News

-

What are the maintenance measures for air permeability tester?

2025-04-02

-

What is the difference between the one-key pre-oxidation alloy melting machine and the ordinary melting machine?

2025-03-25

-

Craftsmanship creates quality! Nanyang JZJ Testing Company successfully delivered 10set customized high-temperature muffle furnaces to help the high-quality development of the refractory industry

2025-03-17

-

How to open the door of a high temperature muffle furnace at high temperature

2025-03-11

-

How to control the heating temperature and time of the multi-function melting machine?

2025-03-05

-

The biggest advantage of the automatic melting machine fusion method

2025-02-25

-

Together we build a quality future - South African customers purchased 3set of T6 melting machines in batches and delivered them successfully, and efficient services help global mining upgrades

2025-02-22

-

Detailed analysis of the advantages of using high-frequency induction multifunctional fusion machine

2025-02-18

-

Indian customers mailed samples to our company

2025-02-11

-

How to avoid uneven temperature distribution in muffle furnace?

2025-02-06

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK