Detailed explanation of the working principle and use of muffle furnace

1.Working principle of muffle furnace

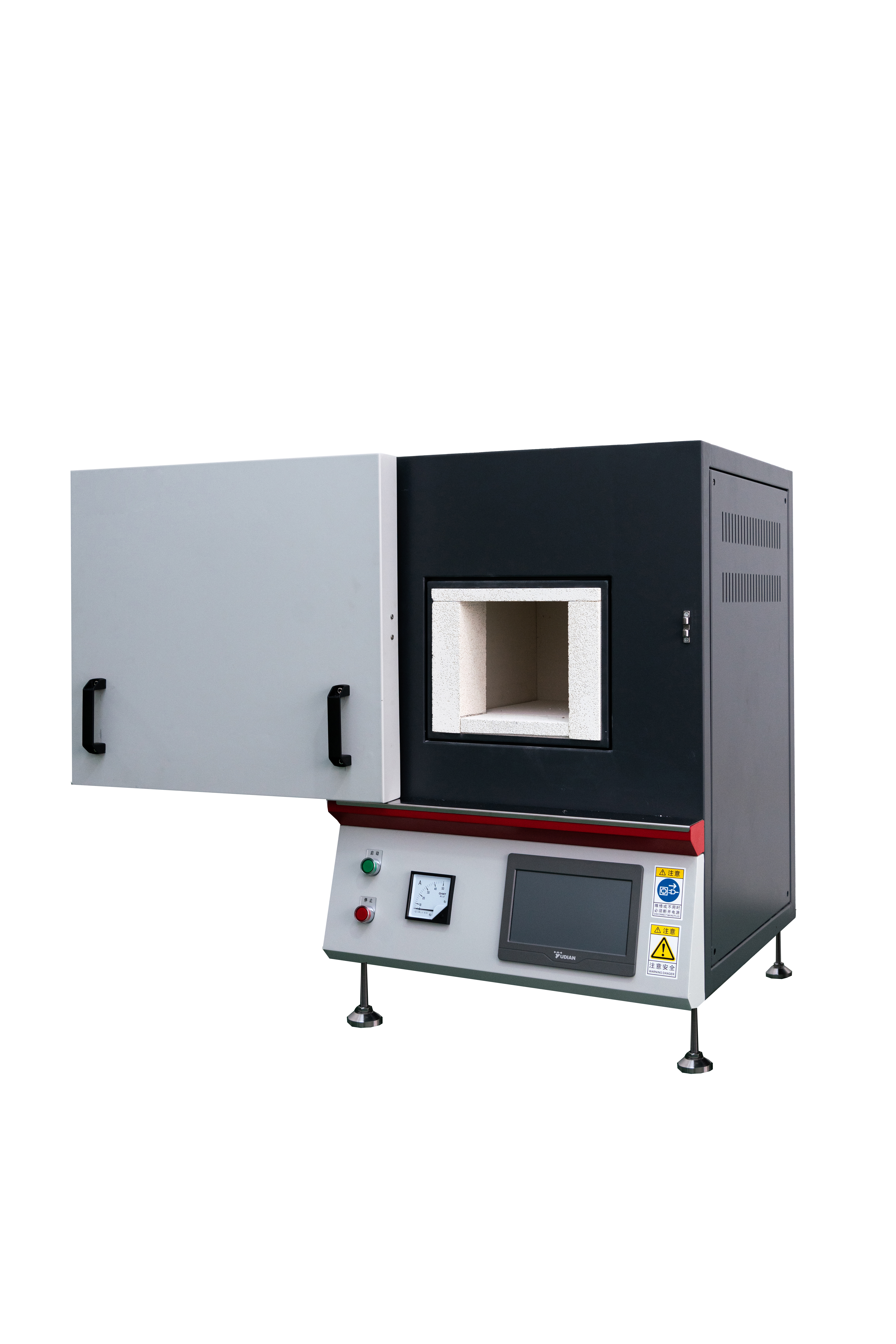

Muffle furnace increases the temperature inside the heater by resistance heating, and transfers the temperature of the heating area to the heated material by heat conduction, so that the material is evenly heated. Its main components include heater, temperature control system and ventilation system. Among them, the heater is heated by resistance heating, the temperature control system controls the temperature to reach the required heating temperature through the temperature sensor, and the ventilation system is used to adjust the atmosphere composition and air pressure in the working environment.

2. Application field of muffle furnace

1). Heat treatment of metal materials

High Temperature Muffle furnace is widely used in the treatment of metal materials, such as preheating, quenching, tempering and annealing of casting molds, automotive parts, tool forgings, etc., so that the material has stronger hardness, toughness and wear resistance.

2). Molding, smelting

High temperature melting furnace is also suitable for heating treatment in various molding and smelting processes, such as glass molding, plastic products, ceramic sintering, etc.

3). Laboratory application

Since the muffle furnace can control the temperature of the heating area, it is widely used in various laboratories and other fields, such as material synthesis, inorganic chemical experiments, high-temperature physical experiments, etc.

In short, as a common heat treatment equipment, the muffle furnace is widely used in the heat treatment, forming, smelting and various laboratories of metal materials. Through resistance heating, the temperature inside the heater can be increased, and the temperature of the heating area can be transferred to the heated material through heat conduction, so that the material is evenly heated.

Recommended Products

Hot News

-

What are the maintenance measures for air permeability tester?

2025-04-02

-

What is the difference between the one-key pre-oxidation alloy melting machine and the ordinary melting machine?

2025-03-25

-

Craftsmanship creates quality! Nanyang JZJ Testing Company successfully delivered 10set customized high-temperature muffle furnaces to help the high-quality development of the refractory industry

2025-03-17

-

How to open the door of a high temperature muffle furnace at high temperature

2025-03-11

-

How to control the heating temperature and time of the multi-function melting machine?

2025-03-05

-

The biggest advantage of the automatic melting machine fusion method

2025-02-25

-

Together we build a quality future - South African customers purchased 3set of T6 melting machines in batches and delivered them successfully, and efficient services help global mining upgrades

2025-02-22

-

Detailed analysis of the advantages of using high-frequency induction multifunctional fusion machine

2025-02-18

-

Indian customers mailed samples to our company

2025-02-11

-

How to avoid uneven temperature distribution in muffle furnace?

2025-02-06

EN

EN

AR

AR

BG

BG

FR

FR

DE

DE

HI

HI

IT

IT

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

MS

MS

UR

UR

BN

BN

KM

KM

LO

LO

PA

PA

MY

MY

KK

KK